Meticulous every step of the way

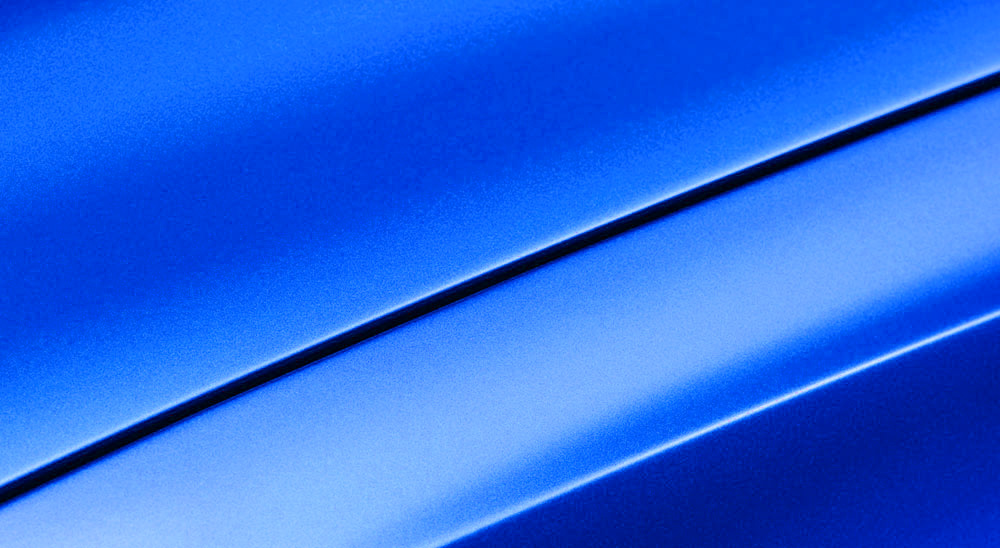

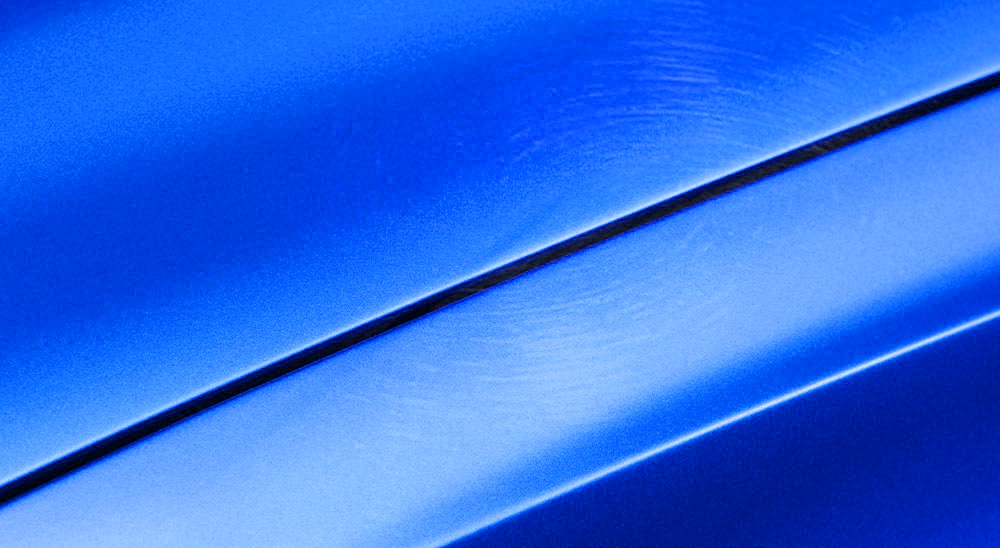

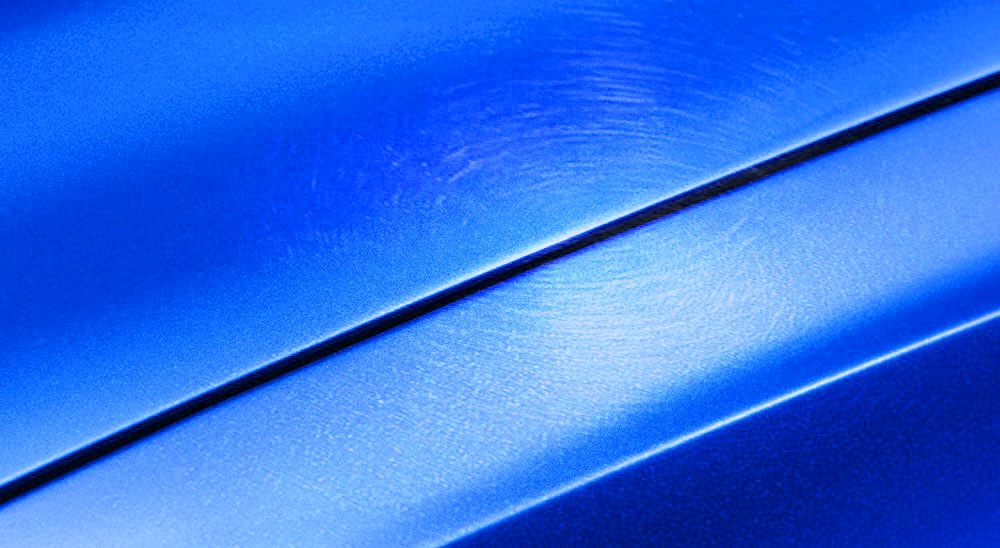

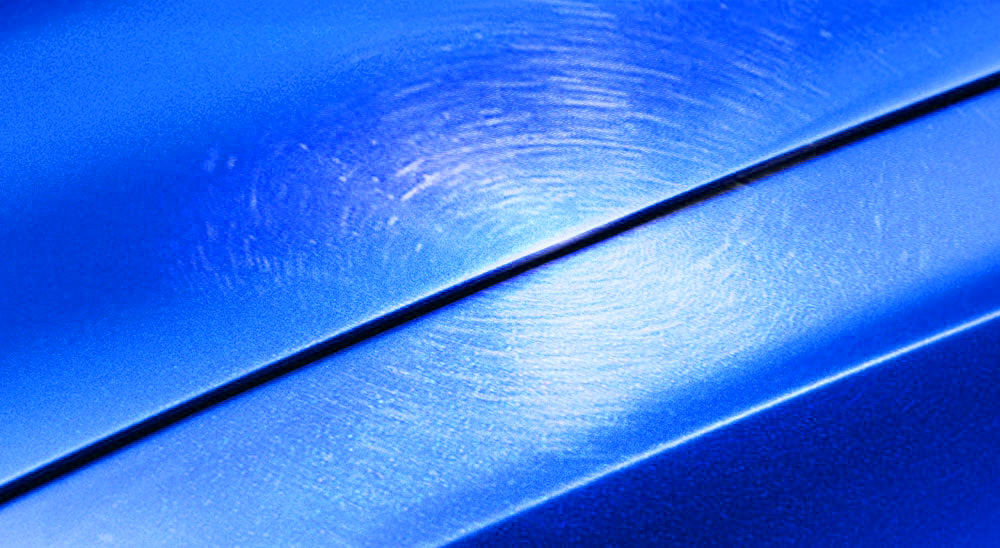

Our Paint Correction & Ceramic Coating Packages offer long-term protection for your investment. Your vehicle will be protected from becoming damaged by chemical etching, UV damage, and environmental contamination.

It will stay cleaner for longer and become much easier to wash and maintain once Coated. Every time it is washed, your vehicle will look super glossy like it was just detailed.

Our meticulous process outlined below was created to yield incredible value and world-class, lasting results. You can rest easy knowing your vehicle is in the hands of true Paint Correction & Ceramic Coating specialist who really care!